0

0

0

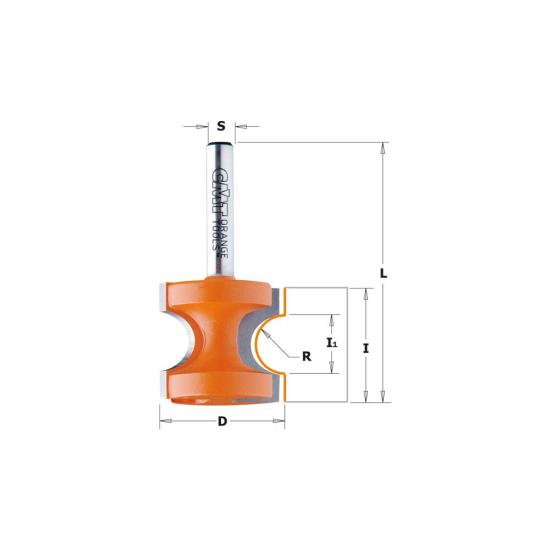

| xShank Diameter(S):xType:xDiameter(D):xLength(L):xRadius(R):xCutting Length(I):xBead Diameter(I1):xSet:Clear All | |||||||||

| SKU | Price | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 854.002.11 | 1/4 | Edging/Profile Bits | 7/8 | 2 | 1/8 | 3/4 | 1/4 | No | $30.89 USD |

| 854.002.111 Available$30.89 USD/ea $45.75 USD | |||||||||

| 854.003.11 | 1/4 | Edging/Profile Bits | 1 | 2-3/8 | 3/16 | 7/8 | 3/8 | No | $34.62 USD |

| 854.003.111 Available$34.62 USD/ea $51.30 USD | |||||||||

| 854.004.11 | 1/4 | Edging/Profile Bits | 1-1/8 | 2-1/4 | 1/4 | 1 | 1/2 | No | $39.45 USD |

| 854.004.11Out of Stock$39.45 USD/ea $58.45 USD | |||||||||

| 854.502.11 | 1/2 | Edging/Profile Bits | 7/8 | 2-1/4 | 1/8 | 3/4 | 1/4 | No | $30.89 USD |

| 854.502.112 Available$30.89 USD/ea $45.75 USD | |||||||||

| 854.503.11 | 1/2 | Edging/Profile Bits | 1 | 2-3/8 | 3/16 | 7/8 | 3/8 | No | $35.41 USD |

| 854.503.112 Available$35.41 USD/ea $52.45 USD | |||||||||

| 854.504.11 | 1/2 | Edging/Profile Bits | 1-1/8 | 2-1/2 | 1/4 | 1 | 1/2 | No | $40.67 USD |

| 854.504.1110+ Available$40.67 USD/ea $60.25 USD | |||||||||

| 854.507.11 | 1/2 | Edging/Profile Bits | 1-3/8 | 2-7/8 | 3/8 | 1-3/8 | 3/4 | No | $54.99 USD |

| 854.507.113 Available$54.99 USD/ea $84.60 USD | |||||||||

| 854.509.11 | 1/2 | Edging/Profile Bits | 1-3/4 | 3-1/8 | 1/2 | 1-5/8 | 1 | No | $60.51 USD |

| 854.509.113 Available$60.51 USD/ea $93.10 USD | |||||||||

| No Matching SKUs. | |||||||||

We understand you're busy and that some things you order may not work out. That's why we give you 90 days to return any unused items. These items must be new, unwashed, and in resalable condition with all manufacturer's tags still attached.

View Our Full Return Policy

All orders over $55 ship for FREE (contiguous U.S. only). Our shipping team takes pride in getting your order out the door as quickly as possible. Most orders placed before 3PM CST will ship out the same business day.

Learn More About Shipping